Tapered Roller Bearings

Tapered roller bearings are bearings especially constructed to endure both radial and axial loads simultaneously even under extreme environmental conditions and varying speeds. The type is composed of four inter-reliant components: the cone, the cup, tapered rollers and the cage. The rolling elements are positioned in a way that all of them meet a common axial point so as to provide a perfect rotating movement with low friction and increased power density..

Spherical Roller Bearings - Brass and steel cage

Marc Spherical Roller Bearings – brass cage have one outer ring which has one spherical raceway and the inner ring has two raceway.Barrel shaped rollers use Between outer ring and inner ring.These bearings can take not only heavy radial loads but they can take also axial loads in either direction Machined brass cage used in these bearings.

Spherical Roller Thrust Bearings

Marc Spherical roller thrust bearings are used in different types of construction mahcinery and equipments These bearings have a number of asymmetrical spherical rollers with cage & washer assembly , Having spered raceway inner & Outer they are capable of carrying both radial load and axial load and in only one direction they are capable for Misallignment because of their internal geometry Thrust load are to be carried from both direction. They are made in india

Spherical Roller Bearings - E-type cage

Marc Spherical Roller Bearings – E type have two stampped window type steel cages, an inner ring without lip(Flanges)and washer(Roller Guide ring) centered on an inner ring or on cage. proudly make in india.

BS2-2RS

Sealed bearings This bearing have the same features and internal design as Spherical roller Bearings they are supplied grease lubricated and should not be washed and are fitted with rubber seal on both side This seal fitted in a groove on the outer ring and seal free on inner ring BS-2-2216-2RS sealed on both sides with filled long ife AP-3 grease lubricaed for the life of the bearing. This product is unique and made in india under our premises.

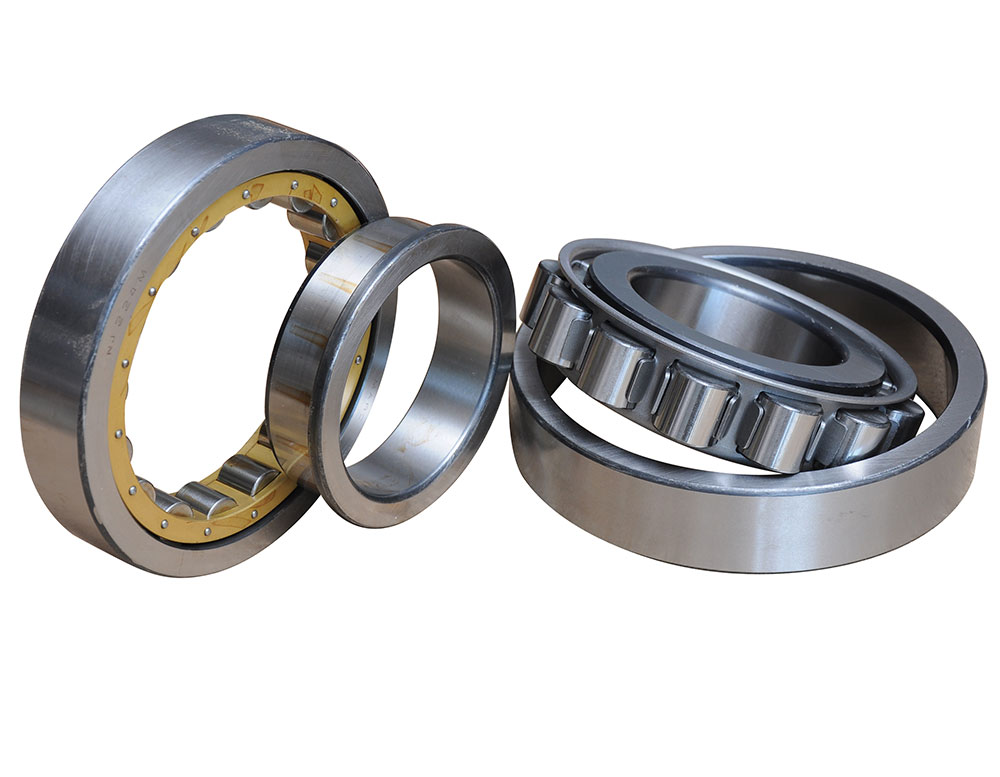

Cylindrical Roller Bearings

Cylindrical roller bearings are designed to withstand heavy radial loads even for high speed applications. These can even bear axial load to a certain extent and also allow a misalignment of about 0.06 degree. The type is easy to assemble and disassemble as both the rings are interchangeable within the specified tolerance and clearance limits. These also have a strong resistance to overloads and shocks that makes them more widely used and accepted in varied industry verticals.

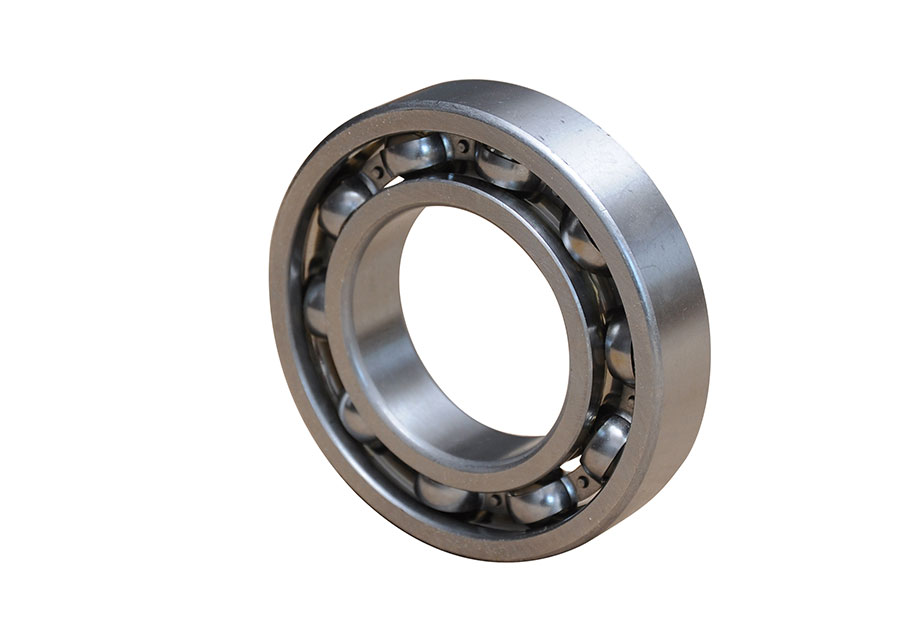

Ball Bearings

Ball bearings are the most common types of bearings designed to withstand both axial and radial load while reducing heat and friction to its optimum. The type comprises of balls between two layers that transmit the load from the outer race to the inner race to ensure smooth performance at a lower coefficient of friction. Apart from the two races and the balls, ball bearings also comprise of:

Special Types of Bearings

Apart from the roller and ball bearings, we manufacture wide range of Special Types of Bearings as per customers design, sample and specifications ranging from 50 mm to 400 mm outer diameter.

Double raw angular contact ball bearings

Marc Double Raw Angular Contact ball bearing have two race way in single inner ring and single outer ring, They can take axial loads in either direction

Double raw Self Aligning Ball Bearings

Marc Double raw Self Aligning Ball bearings have two raceways and the outer rings have a single spherical type raceway with its centre of curvature coincident with the bearing axis

Needle Roller Bearings - Brass and steel cage

Marc Needle roller bearings have very thin rollers with a length 3 to 10 times their diameter,They can use for high radial load capacity These bearings are avaialble in many types : some have no inner ,only outer with cage & roller assemblies. While others have only cage and roller assemblies without rings, some are wihout cages

Forging : inner and outer rings

We purchase raw material from various steel mills according to customer’s approved steel supplier list and international standard & specifications Raw material stored appropriately with Color Code, Heat Number and Section Size wise in seperate racks to easy access and identification. All incoming material inspection for chemical composition and various mechanical and physical properties in NABl Laboratory. Our forge facility is equipped with four friction presses and one Hot Ring Rolling. All l are supported with Long Bar & Cut Piece Induction heating furnaces to achieved desired results in part profile. Total installed capacity for forging is 5000 MT Annually with weight varying from 200 Gms to 40 Kgs. per piece.We do spherodise annealing with scada sysem for maintain material metallurgical Quality

Turning : Inner and outer rings

Forged materialis further used to do turning with the help of automatic CNC machines We have CNC shop with Ace make 5 line CNC machines These machines are known word wide for reliable operation and increased productivity when it comes to manufacturing complicated components with highest degree of accuracy and perfection Chemical and physical testing of each rawmaterial as per control plan. In process inspection as per defined contol plan with referene to drawing

King Pin Bearings

The Kingpin Bearing is capable of bearing thrust load in various industrial pump applications and possesses high resistivity and durability. These are constructed using high grade raw materials. Kingpin bearing is the main pivot in the steering mechanism of a car or other vehicles.